Take a drive around South-Western Ontario to see the fall colours and you’ll also notice a lot of new buildings going up. Farmers are investing in their operations, building new barns, workshops and drive sheds.

The increase in propane costs has lead to a lot of questions about how to heat these buildings more efficiently. The choices available for most rural operations are propane, electric, oil, geothermal and wood.

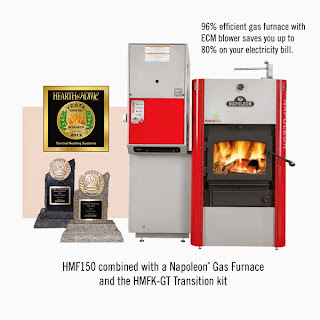

It might surprise people to see wood as one of the choices. We have a company right here in Ontario that is manufacturing wood hybrid furnaces. The name of the company is Napoleon (you many know them for their barbeques) and they have a modern plant in Barrie, Ontario.

A wood hybrid furnace combines wood with a backup fuel source of either oil, electric, natural gas or propane. If you are away for a few days, or run out of wood on a cold night, the backup fuel source kicks in automatically.

Many farms have large wood lots, that always have lots of dead trees. People like to burn wood. It’s more labour intensive, but avoids large fuel bills in the winter when money is not always coming in.

The new Napoleon wood hybrid furnaces are highly efficient. The natural gas or propane furnace they are paired with run at 96% efficiency. Wood efficiency is more difficult to measure, because it varies with the type and quality of the firewood.

A consideration before installing a wood hybrid furnace is that it will require a long-term commitment. Studies have shown that after 3 years, the average Canadian finds they don’t have the time or inclination to continue cutting firewood.

The best way to deliver heat to a workshop is through in-floor tubes. The best time to install these is when you pour the floor for your new shop. In-floor heating is inexpensive to install during construction of a new shop. It leaves you with all sorts of options for what fuel to heat the shop with.

In-floor heating is more comfortable in a workshop. Shops normally have high ceilings. The heat is delivered at the floor, where it is needed. You feel more comfortable at lower temperature settings with in-floor heating. That also saves you on fuel costs.

Boilers can use wood, propane, natural gas, oil or almost any combination you decide. You can also install a geothermal system.

Geothermal systems are the most expensive to install, but the most cost-efficient to run over the life of the equipment. Geothermal is also the most environmentally friendly choice. Geothermal systems can use in-floor tubing or forced air duct work.

Revenue Canada helps soften the blow of installing geothermal with accelerated depreciation schedules. You can write-off 79% of the entire system in three years, and all within 5 years.

The Hayter Group specializes in rural service and installations. Over 75% of the company’s business comes from rural customers. We are well established to service our rural clients from three locations (Chatham, Alvinston and Cambridge).

No comments:

Post a Comment